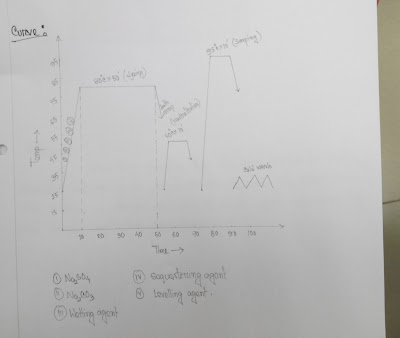

Theory: Reactive dye reach with fabric in presence of alkali

and adheres as a part of the fiber. Three principle steps are happened during

reaction dyeing. Exhaustion or reaction and after treatment as washing when a

cellulosic fibre is immersed into dye solution; negative charge produce and

surrounded the fiber.

On the other band the reactive dyes produce negative

charge into dye both, thus a repulsion force occurred. Use of electrotypes

neutralizes the negative surface charge of the fiber. Due to affinity of the

reactive dye to the fiber acidity the dye molecules move forward to the surface

of the fiber. Thus phase of dyeing is called absorption. Then the dye molecules

diffused into the swelled fiber structure through fiber pores and distribute

over the fib. This step is called exhaustion.Recipe:

Dyes = 3%

Glober salt (Na2SO4) = 60 g/l

Soda (NA2CO3) = 20 g/l

Wetting agent = 1 g/l

Sequestering agent = 1 g/l

Levelling agent = 1 g/l

Temp = 80°C

Time = 50 min

Sample weight =5 gm

Neutralization:

CH3COOH = 1 g/l

Temp = 50°C

Time = 10 min

Soaping:

Detergent = 1 g/l

Time = 10 min

Temp = 95 °C

Friction of the chemical required:

Wetting agent: It accelerates the wettability of material in

solution thus helps to easy penetration of chemicals into substrate.

Sequestering agent: it one kind of surfactants surface

active agent act in solid liquid , solid gas or liquid gas interfaces and

reduces the interfacial tension.

Levelling agent: Levelling agent is used in textile

coloration process to active uniform dyeing over whole substrate by controlling

the rate of dyeing.

Electrolytes: Use of electrolytes neutralizes the negative

surface charge of fiber.

Recipe calculation:

Dye: 100 gm fabric for

3 gm dye

1 gm

“ “ 3/100 “

5 gm

“ “ 3×5 / 100 “ = 0.15 gm

Water: 200 gm [ m:L = 1:40]

Na2SO4 = 1000 CC water, NA2CO required = 60 gm

1 “ “ “ =60 / 1000 “

200 “ “ “ = 60 × 200 / 1000 gm = 12g

Similarity,

NA2CO3

= 4 g/l

Wetting agent = 0.2 g/l

Sequestering agent = 0.2 g/l

Levelling agent = 0.2 g/l

CH3COOH = 0.2 g/l

Detergent = 0.2 g/l

Conclusion: Now-a day reactive dyes are very popular for

textile coloration because of its some specific properties like color fastness

wide range of shad, brilliance of shade , good reproducibility and simple

application procedure.

Discover the ultimate solution for accurate moisture analysis in textiles with our Textile Moisture Meter.

ReplyDeletethank you!!

Wow, I came to learn about machines, and your information is absolutely amazing! For more insights and if your are looking for the Lockstitch Sewing Machines

ReplyDelete! we provide high-speed Lockstitch Sewing Machines with eco-friendly motors and technical support !