Theory: Disperse dyes are non-ionic

in nature, almost insoluble and stay as finely divided dispersed from in water.

It can be hydrolyzed in high temperature especially under alkaline condition. Therefore

dyeing with disperse dyes is virtually always done using slightly Acadia condition.

It is a unique dye staff for dyeing of polyester, nylon and cellulose acetate

fiber.

These colorants have inherent affinity to the fiber and are simply

mechanically trapped in the fiber structure during dyeing of a hydrophobic

fabric contents that the fiber absorbs dye molecule, which are dissolved in the

dye both.

Disperse Dyes = 1.5% (owf)

Carrier = 2 g/l

Wetting agent = 1 g/l

Sequestering agent = 1 g/l

CH3COOH = 1 g/l

Ph = 4.5 – 5.5

Temp = 80°C

Time = 35 min

Sample weight =5 gm

Reduction & Cleaning:

NaOH = 3 g/l

Hydroze = 2 g/l

Temp = 70°C

Time = 10 min

Neutralization:

CH3COOH = 1 g/l

Temp = 50°C

Time = 10 min

|

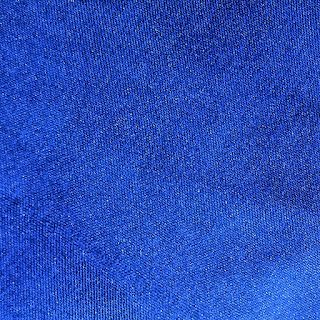

| Fabric type - Carrier Fabric Name - Polyester color - Blue |

Friction of the chemical required:

Wetting agent: It accelerates the wetability of material in solution thus helps to easy penetration of chemicals

into substrate. Usually it is used in scouring, bleaching & dyeing process.

It is available in market in from of yellowish liquid.

Sequestering agent: It one kind

of surfactants surface active agent act in solid liquid, solid gas or liquid

gas interfaces and reduces the inter-facial tension.

Dispersing agent: It is

used in disperse and vat dyeing process helps to distribute the dye molecules

in dye both. It is also helps to penetrate the dye molecules into the

substrate. It is available in market in powder from.

Recipe calculation:

Dye: 100 gm fabric for 1.5 gm dye

1

gm “ “

1.5/100 “

5

gm “

“ 1.5×5 / 100 “ = 0.075 gm

Water: 200 gm [ m:L = 1:40]

Carrier , 1000

CC water, Carrier required =

2 gm

1 “ “ “ =60 / 1000 “

200 “ “ “ = 2 × 200 / 1000 gm = 0.4g

Similarity,

Wetting agent = 0.2 g/l

Sequestering agent = 0.2 g/l

CH3COOH = 0.2 g/l

Reduction & cleaning:

NaOH = 0.6 gm

Hydroze = 0.4 gm

Neutralization:

CH3COOH = 0.2 g/l

|

| Add caption |

Conclusion: The addition of

dispersing agent increase the dye solubility and accelerate the dye diffusion

into the swelled fiber structure. The dye diffusion can be detained either. Using

a suitable currier or providing high temperature and pressure.

No comments:

Post a Comment