Theory: azoic dye are not ready

mode dyes like reactive dyes. The insoluble azoic colors are synthesized inside

the fiber by coupling of two individual components neither of which is a dye

itself. These two components are on aromatic diezoniem

solt and an aromatic

hydroxyl compound. After diazotization the actual color is developed in the

substrate. In application of azoic colors, the first step is selecting the west

suitable diazo and coupling components combination of a particular purpose is

to decide which of the napthols can be used in conjunction with the available

diazo components to give the color closest to the chemical shade and depth. |

| Fabric type : Cotton Dye type : Azoic Color : Orange |

Recipe:

1st step

Naptholation:

napthol = 2% (owf)

NaOH = 3 g/l

NaCl = 5 g/l

Wetting agent = 1 g/l

Sequestering agent = 1 g/l

Levelling agent = 1 g/l

Ph = 10

Temp = 30°C

Time = 15 min

Sample weight =5 gm

Base = 2% (owf)

CH3COONa= 2 g/l

HCL = 2 g/l

NaNO2 = 2 g/l

Wetting agent = 0.5 g/l

Sequestering agent = 1 g/l

Levelling agent = 1 g/l

Temp = 5°C

Time = 15 min

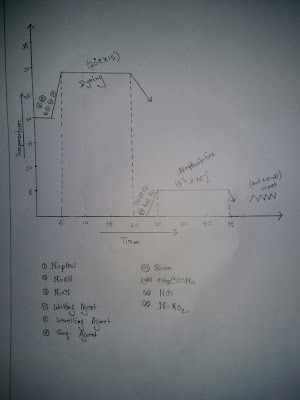

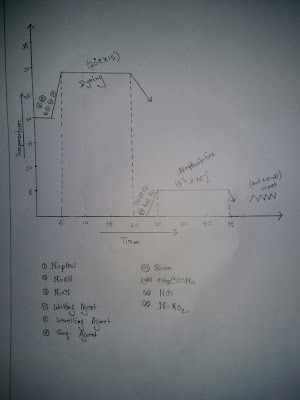

Curve For Azoic dye

|

| Curve For Azoic dye |

Wetting agent:

It accelerates the

wettability of material in solution thus helps to easy penetration of chemicals

into substrate. Usually it is used in scouring, bleaching & dyeing process.

It is available in market in from of yellowish liquid.

Sequestering agent:

it one kind

of surfactants surface active agent act in solid liquid, solid gas or liquid

gas interfaces and reduces the interfacial tension.

Recipe calculation:

Dye: 100 gm fabric for 2 gm naphthol

1

gm “ “

2/100 “

5

gm “

“ 2×5 / 100 “ = 0.1 gm

Water: 200 gm [ m:L = 1:40]

NaOH , 1000

CC water, Carrier required =

3 gm

1 “ “ “ =3 / 1000 “

200 “ “ “ = 3 × 200 / 1000 gm = 0.6g

Similarity,

NaCL = 1 gm

Wetting agent = 0.2 g/l

Sequestering agent = 0.2 g/l

Levelling agent = 0.2 gm

2nd process:

Dye: 100 gm fabric for 2 gm base dye

1

gm “ “

2/100 “

5

gm “ “

2×5 / 100 “ = 0.1 gm

Water: 200 gm [ m:L = 1:40]

NaOH ,

1000 CC water CH3COONa required = 2 gm

1 “ “ “ =2 / 1000 “

200 “ “ “ = 2 × 200 / 1000 gm = 0.4g

Similarity,

HCL = 0.4 gm

NaNO2 = 0.4 gm

Wetting agent = 0.1 g/l

Sequestering agent = 0.2 g/l

Levelling agent = 0.2 gm

Conclusion: Azoic dye are

commonly used for dyeing of cotton although other cellulose fibers, wool and

even some synthetic fiber as well the main advantage of this dyes is that

produce an economical way to abtain certain shade especially red with very good

wash fastness.

No comments:

Post a Comment