Introduction of Sizing:

Sizing is the formula of applying a protective adhesive application on the surface of the spinning. This is the largest of the preparatory segment of the textile process. The old saying that the design is the heart of the canvas is still valid today. This argument is extremely important in the current context where the increase in imminent speeds ten times higher than those used in the shuttle.

Gluing machine can be classified according to the drying method is as follows:

Conventional aqueous primer:

Double cylinder scalable: It consists of entirely two of the drying cylinder or two square planting arrangement leading to more energy ingestion.

Scaling is traditional:

Scalable Sec:

This is done by dry powder spray on the paper size chain and is believed to the size of the powder to be fixed stylish the warp due to electrostatic attraction force. This process assures the reduction in the cost of raw materials and reduce pollution.

This is attained by using organic solvents scalable processing non-aqueous media instead of irrigate: Vector solvents. Hydrogen is used primarily in the chlorinated solvent is necessary and 1/10 of the energy to evaporate the solvent.

Melt scalable:

Fabric suitable for high speed, for example, the shuttle less looms where there is a risk of hair yarn. It is scaled in the deformation device includes a special device called the penis size. Size is preserved in the form of cake where are kept the pressure on Warp.Scalable mix:

synthetic fibers are a lot of sensitive to heat up and voltage. But the size of the success better than cotton performance will result in 100%. To perform well blend the needs of both grading machines as considerably as operating requirements. |

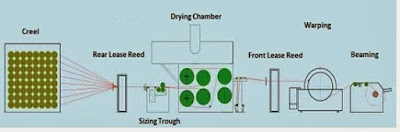

| Fig - 2: Non-Conventional Sizing Machine |

No comments:

Post a Comment